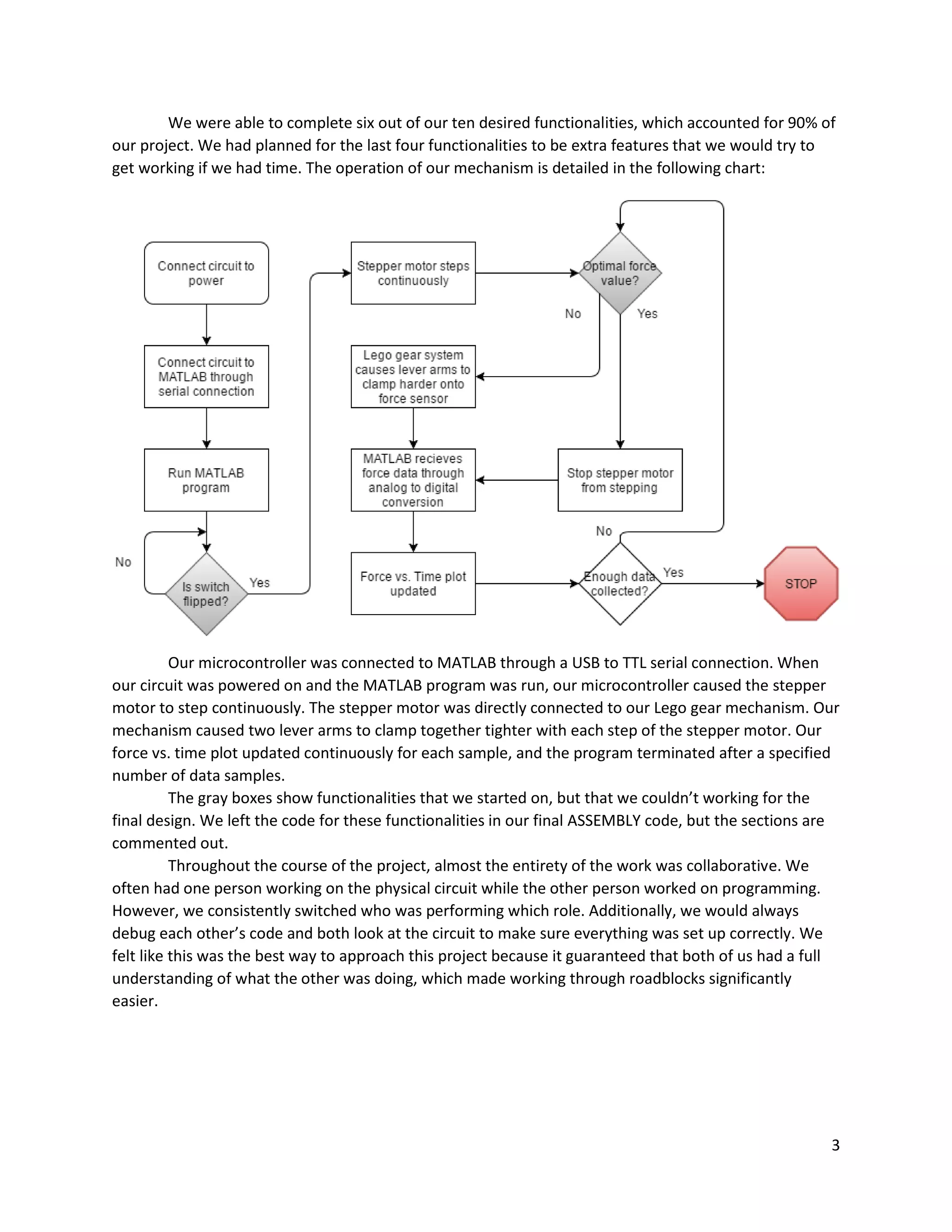

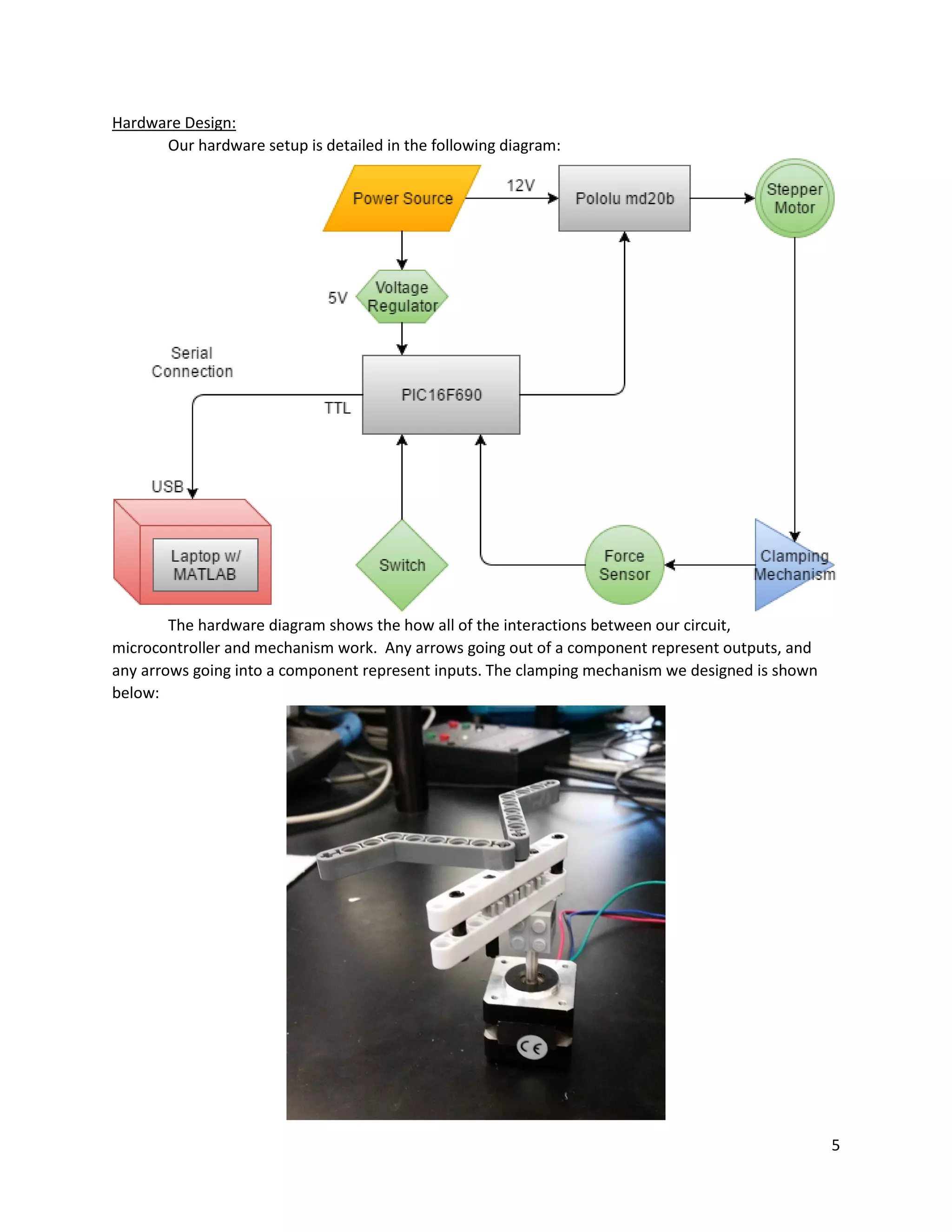

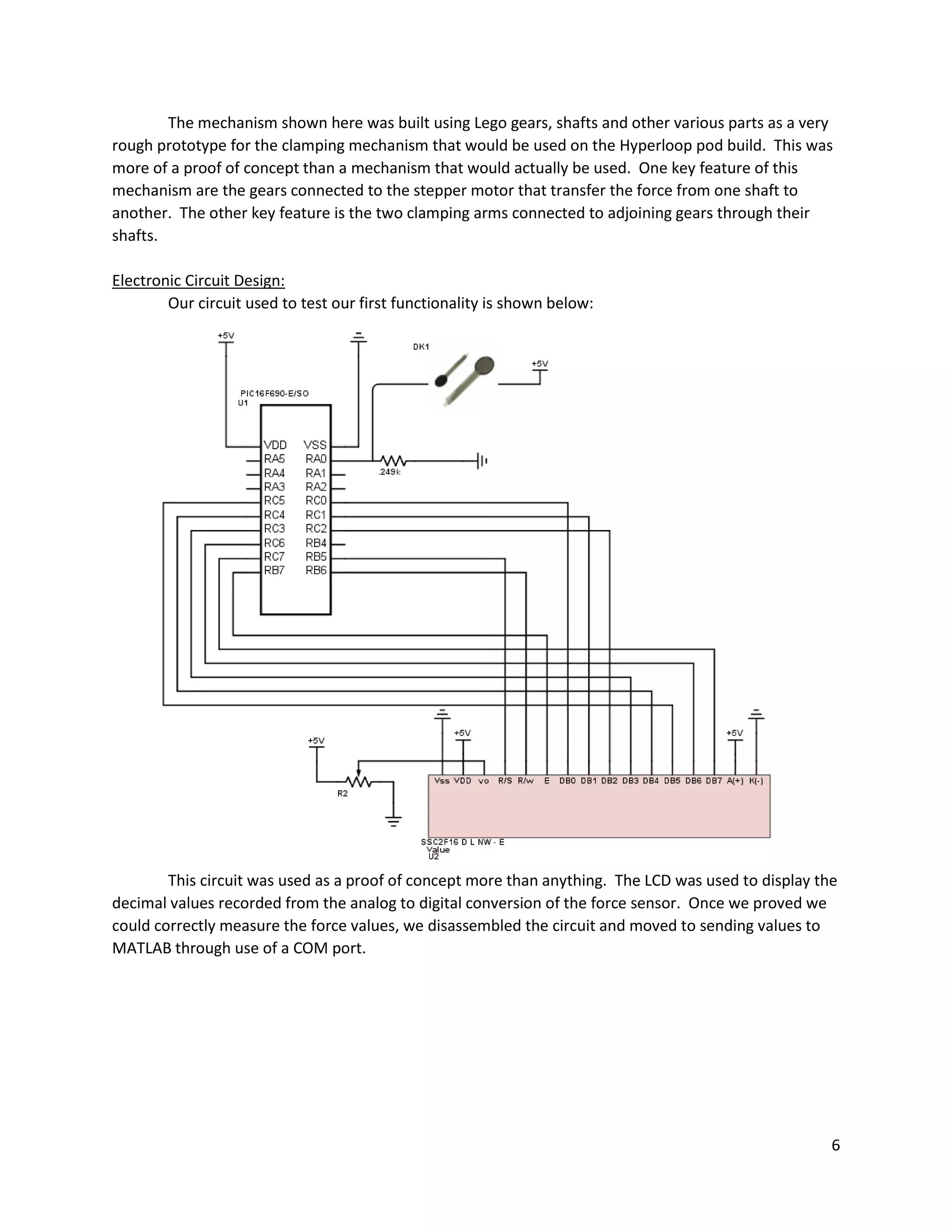

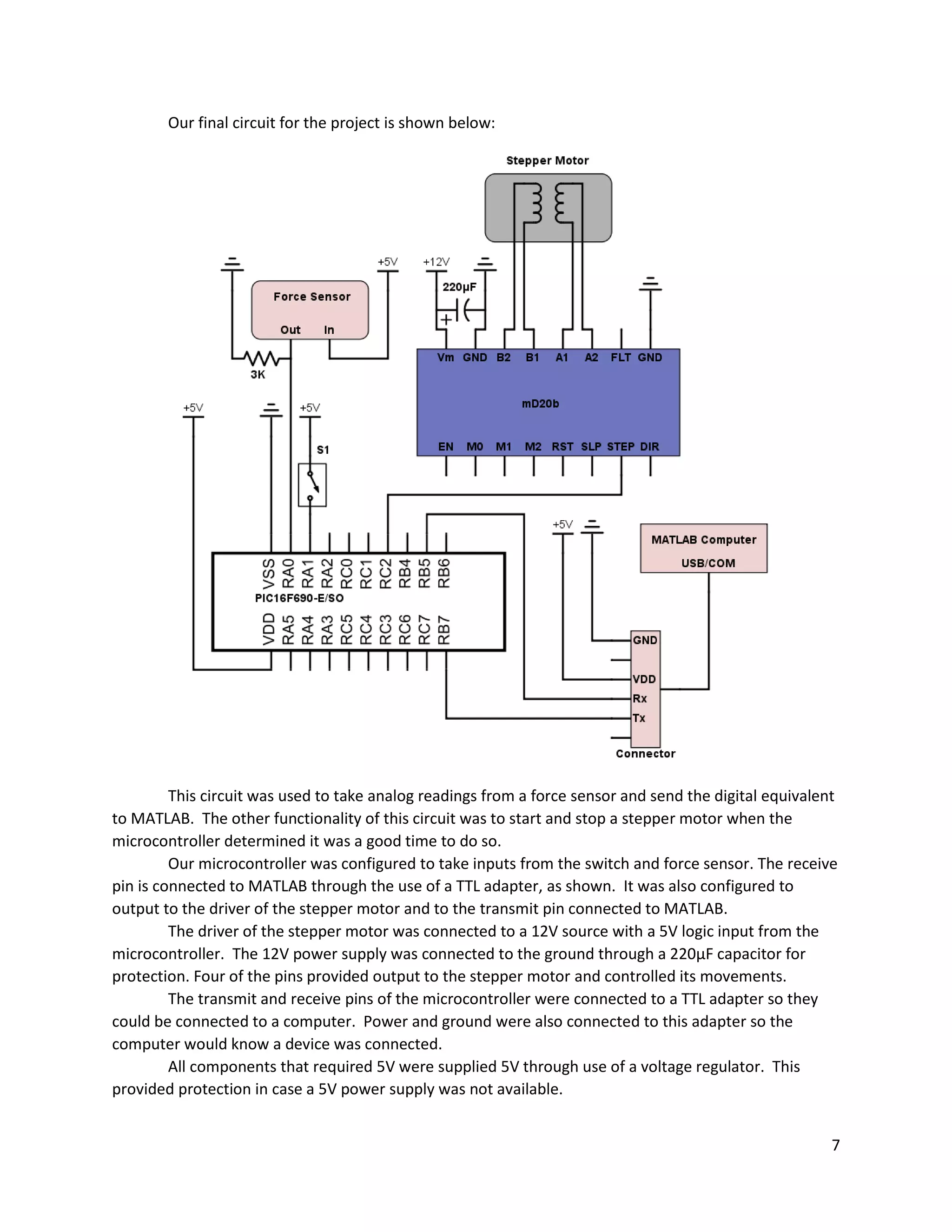

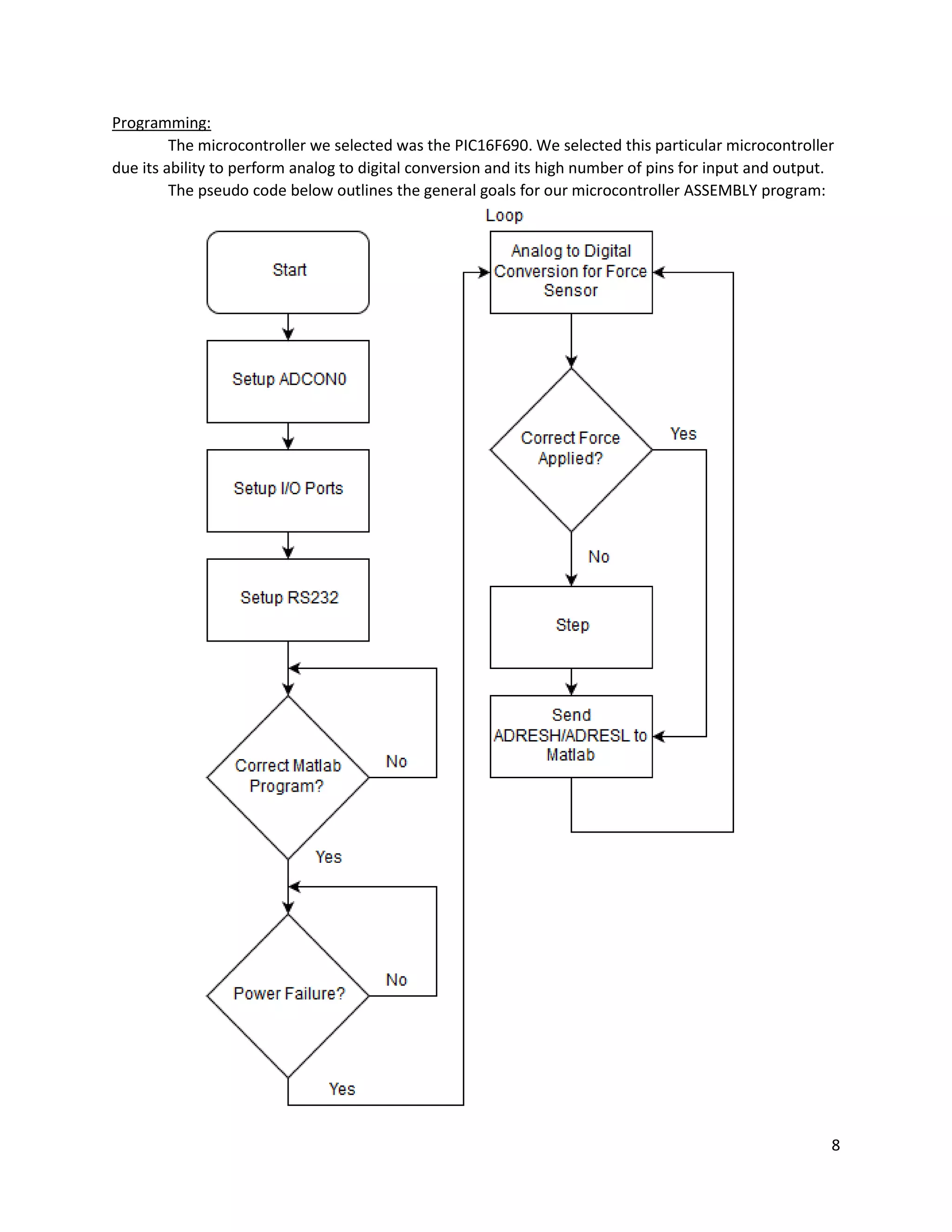

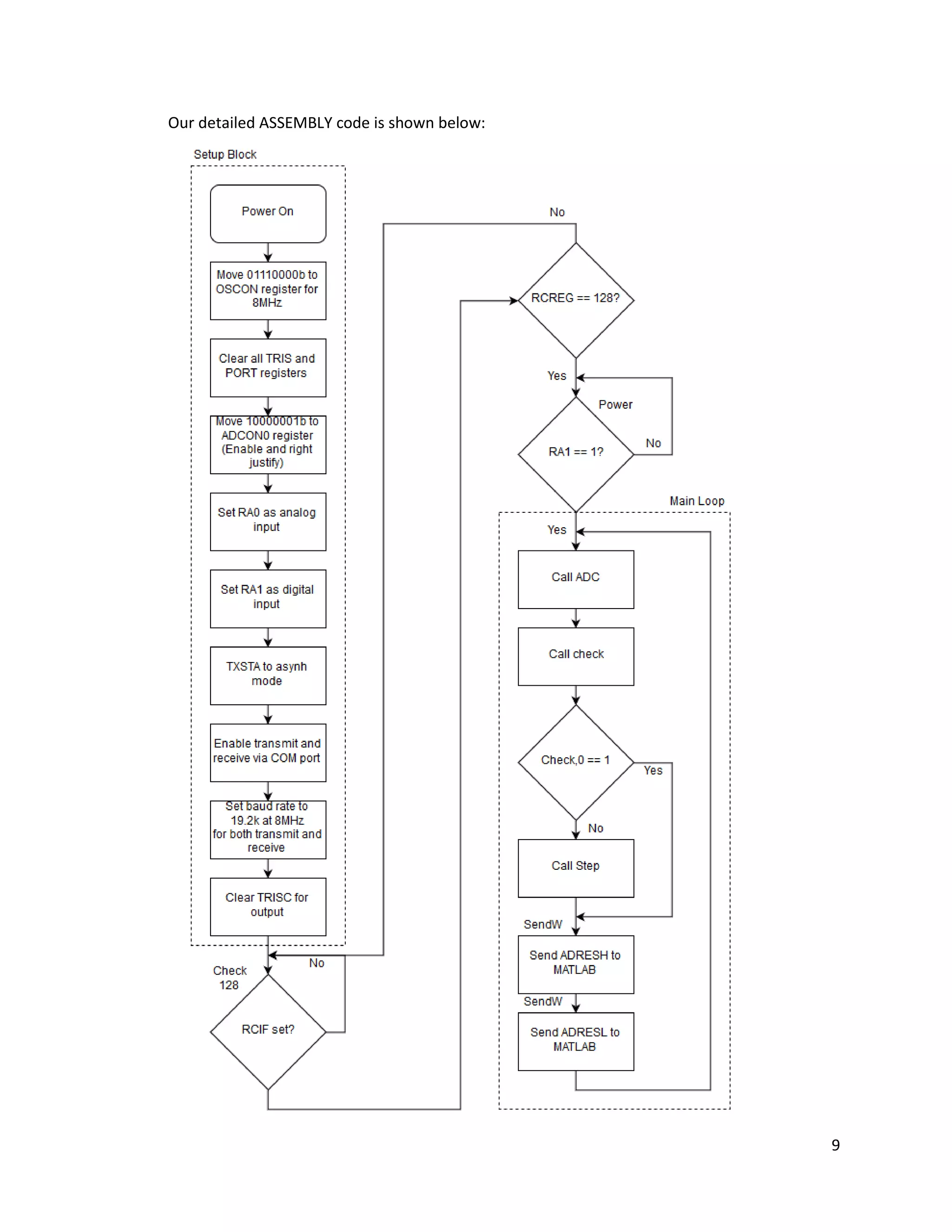

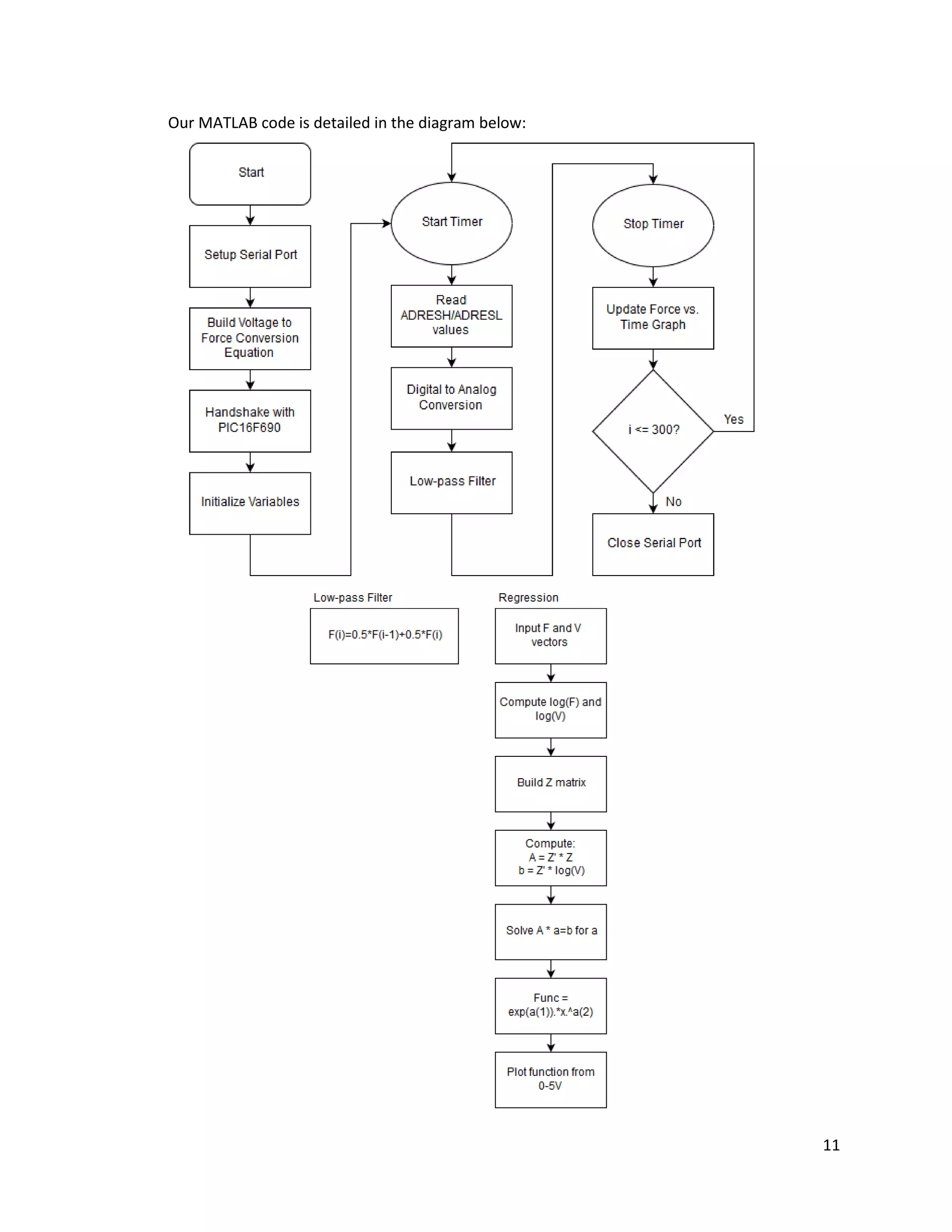

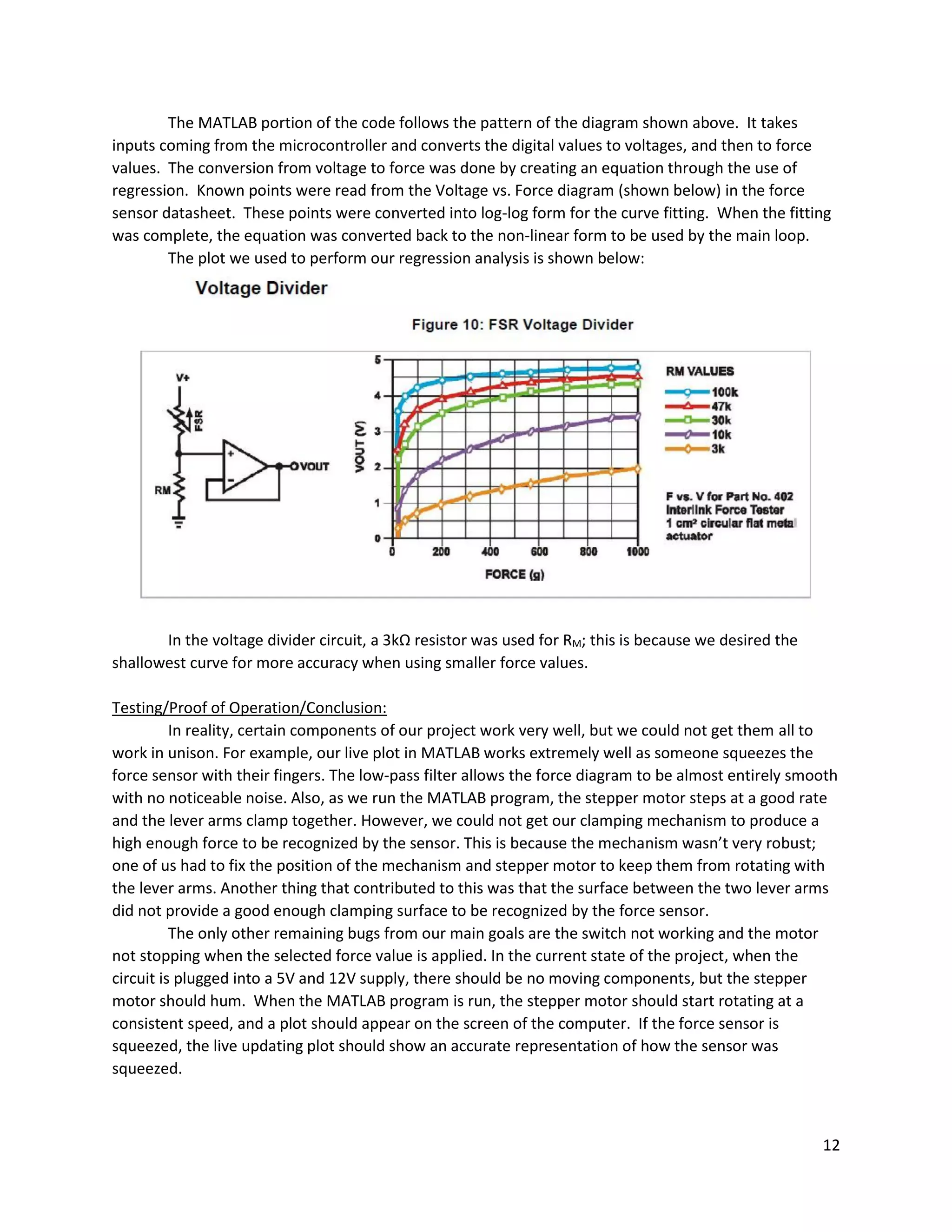

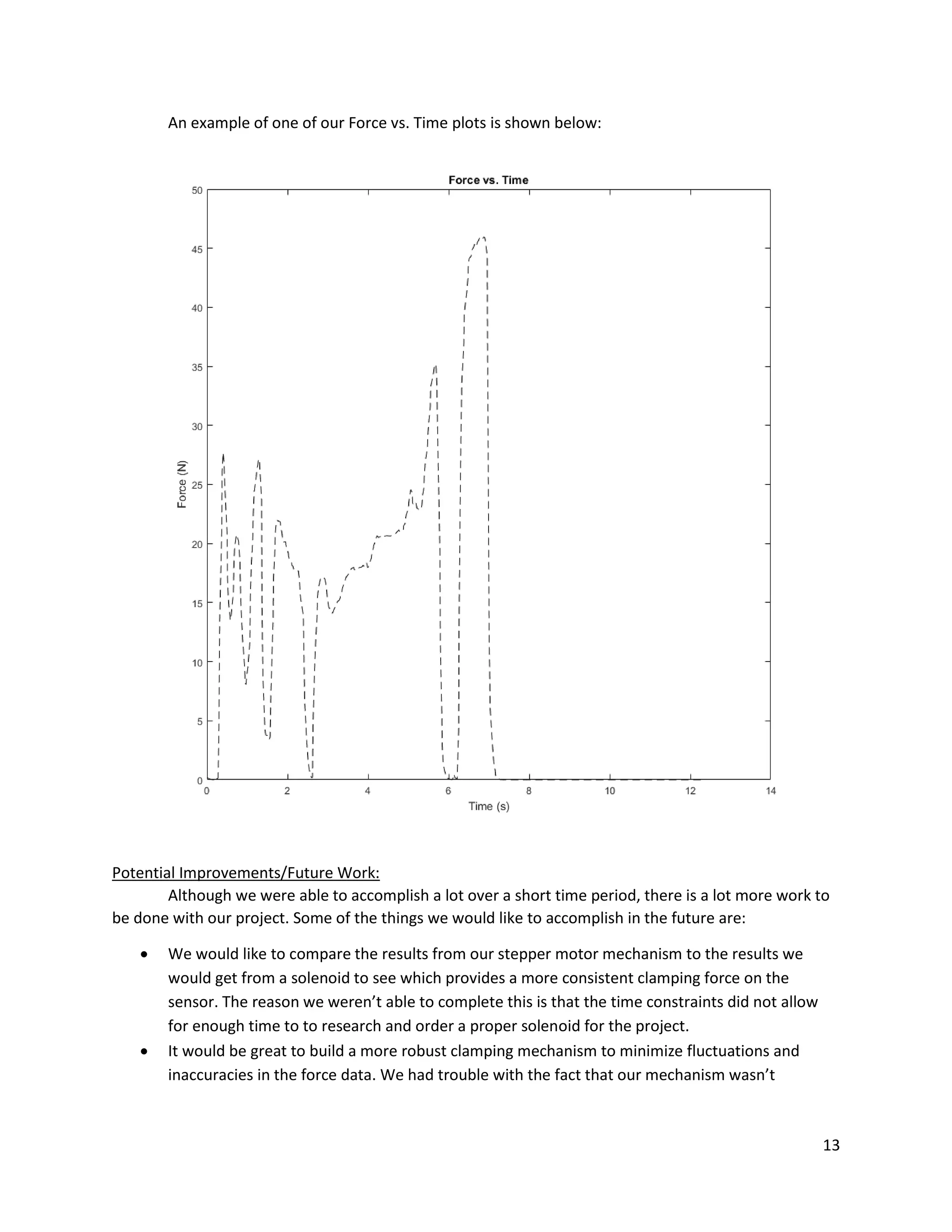

This document describes a student project to design an emergency braking system for a Hyperloop pod. The system uses a stepper motor mechanism to apply a controlled clamping force on a force sensor. The force values are sent to MATLAB via a microcontroller for visualization. The goals were to control the clamping force and stop it at a specified force value. While most functionalities worked individually, integrating them proved challenging within time constraints. Potential improvements include optimizing the clamping mechanism and simulating electrical failure with a switch.

![25

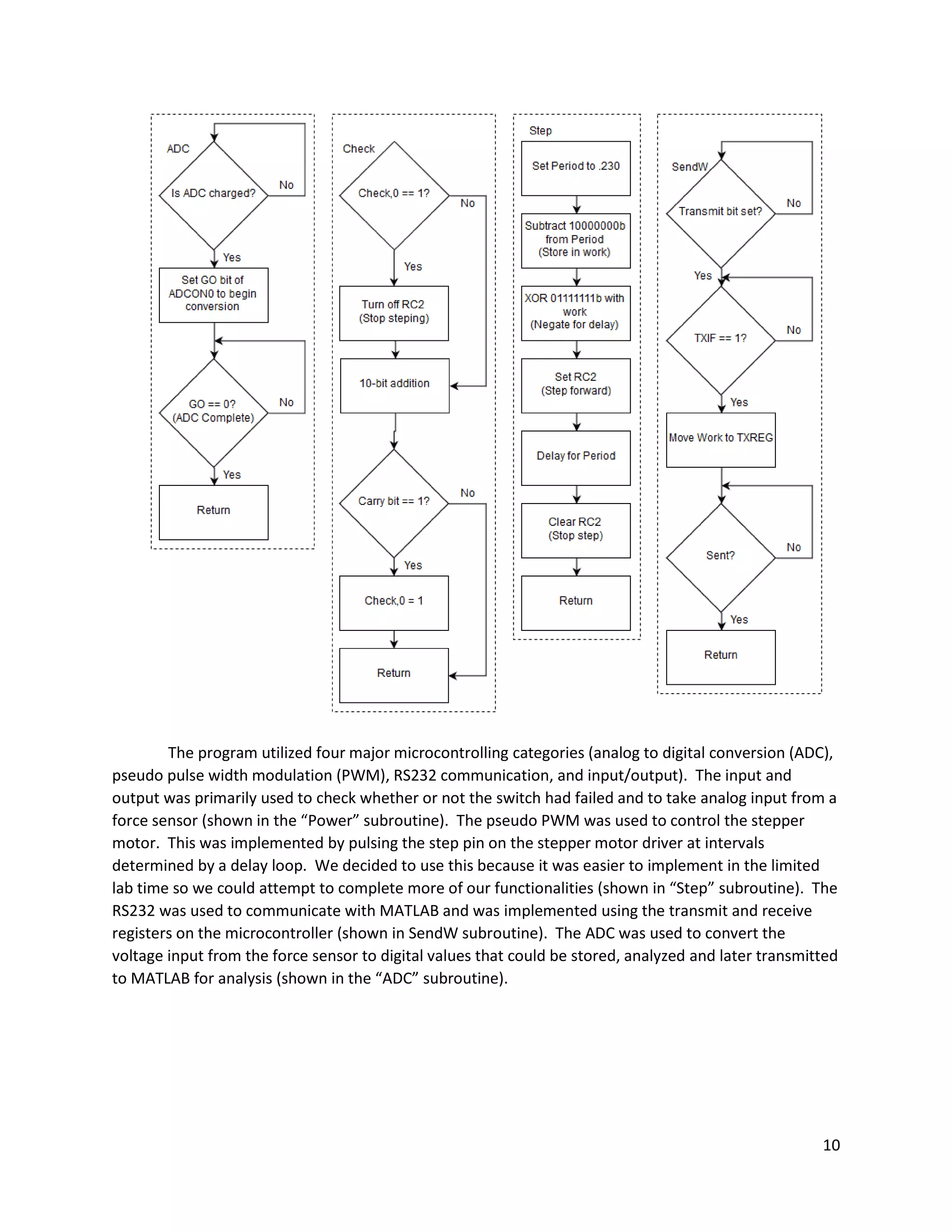

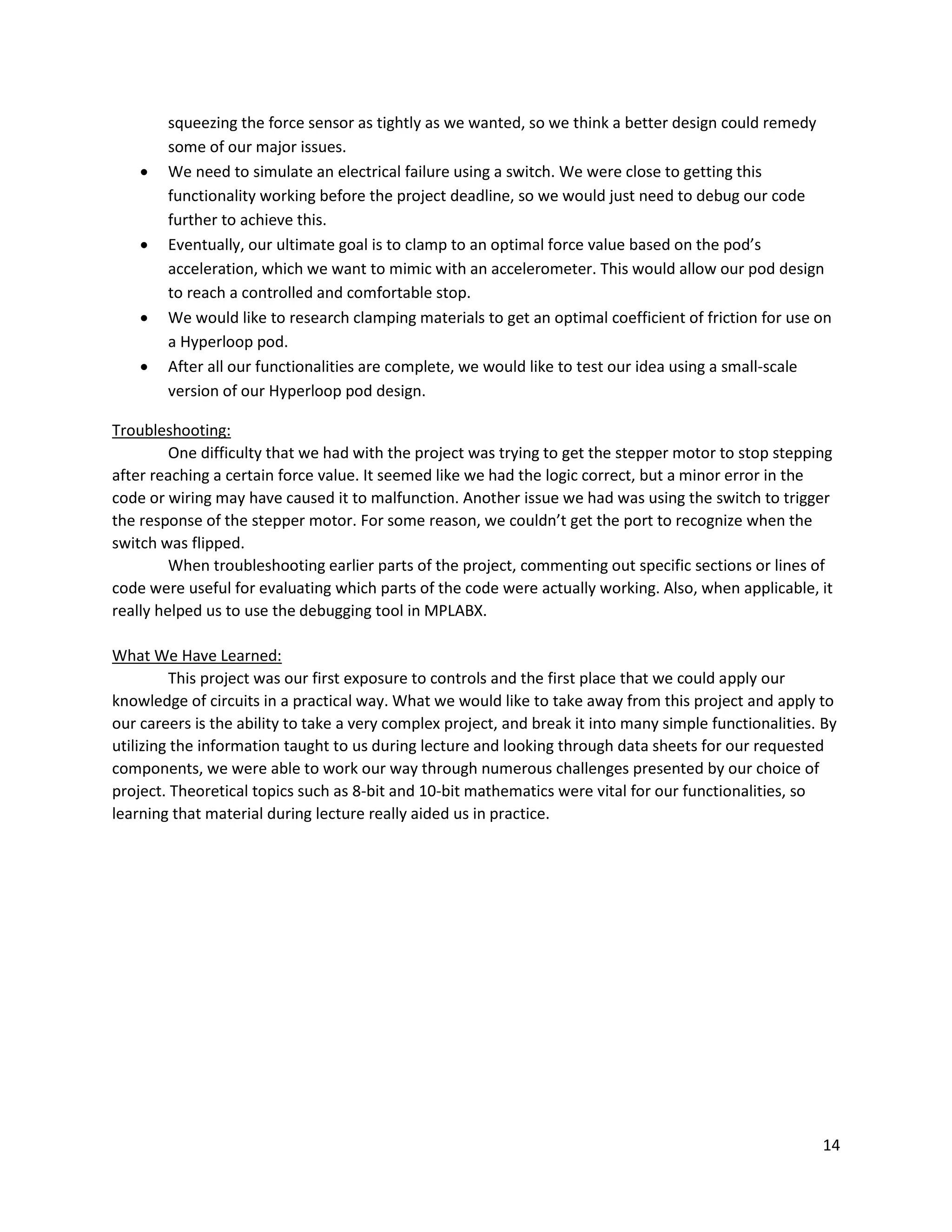

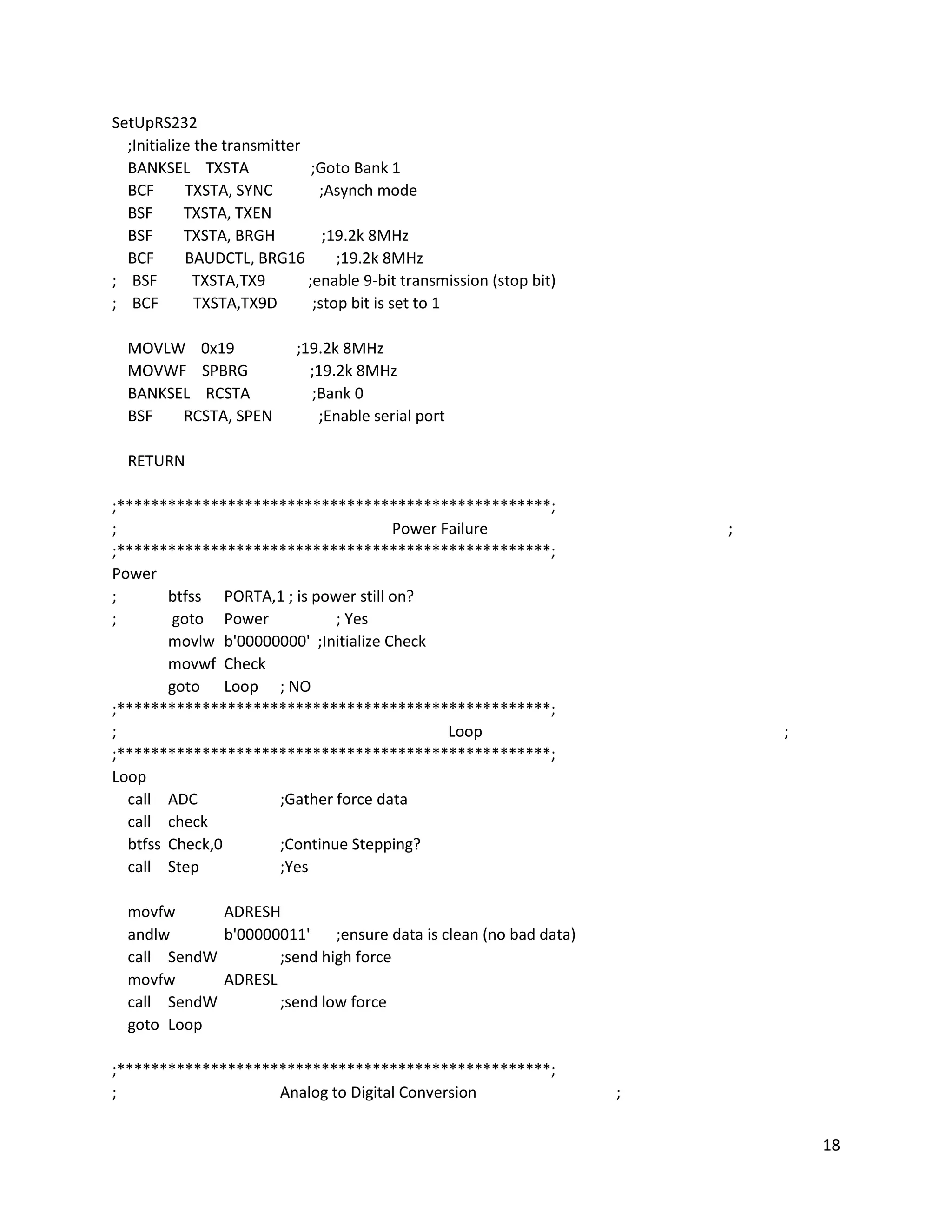

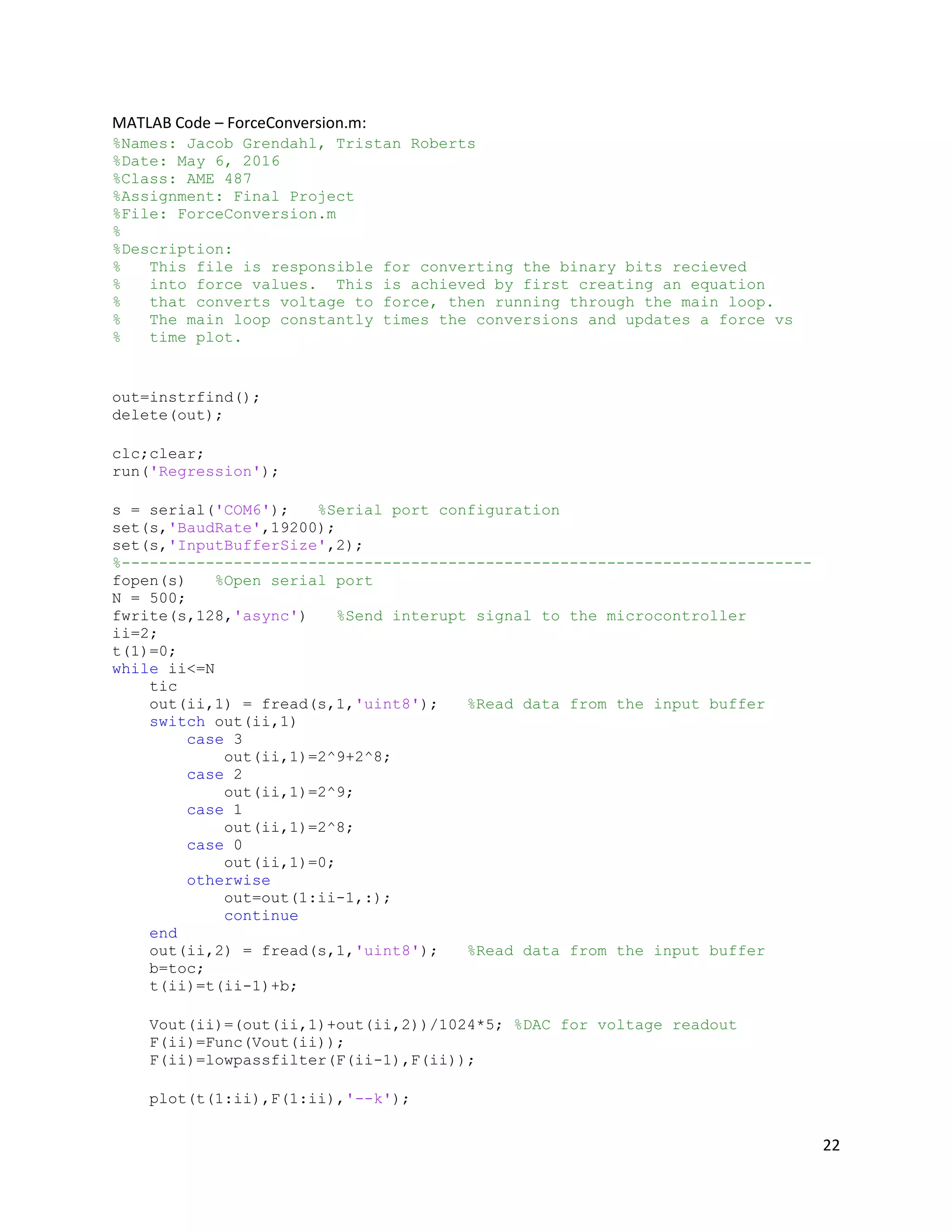

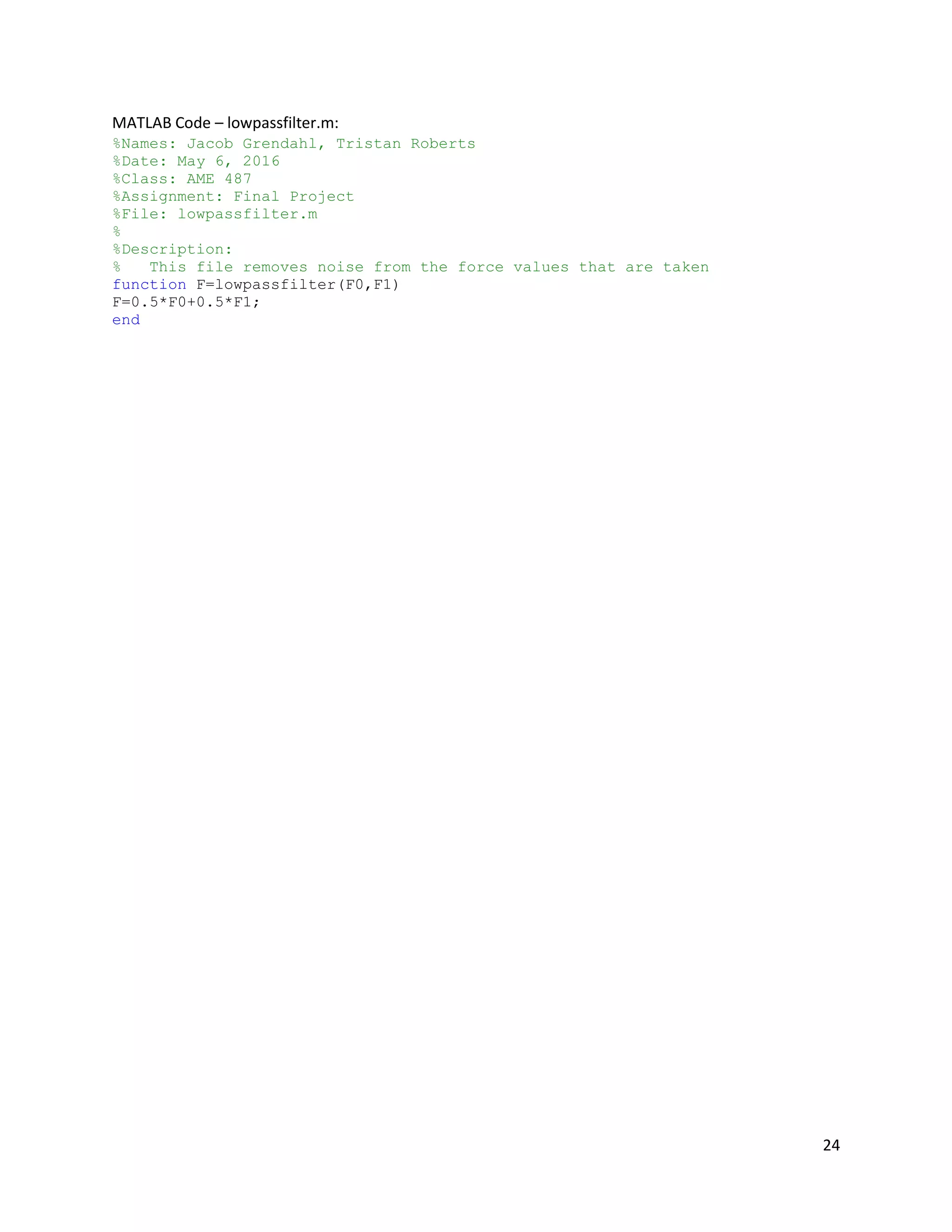

MATLAB Code – Regression.m:

%Names: Jacob Grendahl, Tristan Roberts

%Date: May 6, 2016

%Class: AME 487

%Assignment: Final Project

%File: Regression.m

%

%Description:

% This file is resopisible for building the equation that converts

% voltage to force values.

F=9.8/1000*[20 50 95 195 310 440 570 705 900 1000];

V=[0.35 0.5 0.7 1 1.2 1.45 1.625 1.8 1.95 2];

X=log(V);

Y=log(F);

Z=[ones(length(V),1) X'];

A=Z'*Z;

b=Z'*Y';

a=Ab;

x=0:0.1:5;

y=exp(a(1)).*x.^a(2);

Func=@(x)exp(a(1)).*x.^a(2);

plot(V,F,'or',x,y,'-k');

xlabel('Voltage Out (V)');

ylabel('Force (N)');

title('Force vs. Voltage Output');](https://image.slidesharecdn.com/ddf3549b-2c02-4abe-9127-e5003cd161e0-160825040156/75/Team2_Final_Project_Documentation-25-2048.jpg)