We took a test-drive of NASA's new moon rover candidates

A retro-futuristic space truck. A nimble crustacean on wheels. A space-age dune buggy. One will win a multibillion-dollar prize to deploy on a future NASA Artemis mission. But first, we took a ride on all three.

Before me is an expansive, arid landscape—a realm of valleys, chasms, and crevasses, of steep cliffs and dusty soil, framed by distant mountains. It might as well be on the moon itself, save for the scattered scrub, azure sky, and occasional rattlesnake.

Not too far back, on the dirt road, you can spot a signpost: LUNAR VEHICLE TEST SITE. This is no ordinary patch of desert. “I get to come out here and drive space trucks,” says Justin Cyrus, the CEO of Lunar Outpost, with a grin, surveying his playground.

A prototype of a vehicle he hopes to send to the actual moon stands nearby, its platinum-hued paint gleaming in the sun. It’s adorned with top-mounted solar panels, wide side radiators to reemit that scorching dayside lunar heat away from the vehicle, flat work benches, and various types of rock sample storage. In the middle there’s a wide-open, spacious, two-seated cockpit decorated by navigation screens. It’s a far cry from the moon rovers of the Apollo era, which looked like go-karts in comparison.

A few years back, NASA threw down the gauntlet to the aerospace industry, saying: We need you to design and build the next-generation moon rover for the upcoming Artemis missions. Who’s up to the task?

The Artemis-era lunar terrain vehicle, or LTV, needs to be part speedster, part workhorse—a vehicle that can survive one of most treacherous environments known, all while conducting cutting-edge scientific investigations and laying the foundations of a future moon base.

In 2024, three U.S.-based companies were selected to compete for NASA’s multibillion-dollar LTV contract: Lunar Outpost, Venturi Astrolab, and Intuitive Machines. All three LTV designs are strikingly different. Lunar Outpost’s, glinting before me in the midday sun, looks like a retro-futuristic space truck. The second is a nimble and compact crustacean on wheels, and the third is a space-age dune buggy. They are all turning “science fiction into fact,” says Tim Crain, a co-founder of Intuitive Machines. “We’re doing something amazing. We might as well have a little bit of fun with it.”

It’s likely all three LTVs will journey to the lunar surface on commercial missions, each of which could help build a working economy on the moon—a place with science labs, mining sites, and communications arrays. That’s “the future we’re excited about,” says Jaret Matthews, founder and CEO of Astrolab.

But just one of these next-generation rovers will become the ultimate off-road vehicle for NASA’s Artemis astronauts, who will use the competition’s champion to tear up the lunar surface.

The winner is set to be announced by year’s end. Before that, National Geographic asked all three companies the same question: Can we take them for a test-drive?

What a 21st Century moon buggy needs

The Apollo program decisively ended the original space race. Now a second is at full throttle, one in which both governmental space agencies and private companies are angling to make their mark on the moon. With Artemis, NASA’s new lunar exploration effort, the goal isn’t just to plant more flags. Instead, it’s to establish a permanent presence up there, to lay the foundations for a base on the moon’s south pole—a fortress among the stars.

Astronauts can help set up lunar infrastructure, but their visits to the moon will be fleeting. LTVs, however, can be there all the time. Whether they are being driven remotely from Earth or scooting themselves around the lunar surface autonomously, they are the tireless construction workers and scientific investigators that the Artemis program needs.

The lunar south pole is a promising place to set up a base: Its regolith is thought to be suffused with water ice, which can hydrate astronauts, grow crops, and make rocket fuel. Unfortunately, it also happens to be one of the solar system’s most lethal environments.

With no atmosphere, its daytime temperatures can spike at 250°F, while at night they can drop to minus 208°F; some of its ice-filled craters are in permanent shadow, and the mercury can plummet to minus 410°F. Solar eruptions can bombard the unprotected lunar surface with intense radiation—a potentially fatal danger to humans and electronics alike. Small micrometeorites, which are effectively stone space bullets, collide with the moon all the time. And these impacts violently blast lunar soil in all directions, creating an electrically charged, adhesive, and highly abrasive dust that can eat through space suits and wiring like microscopic space piranhas.

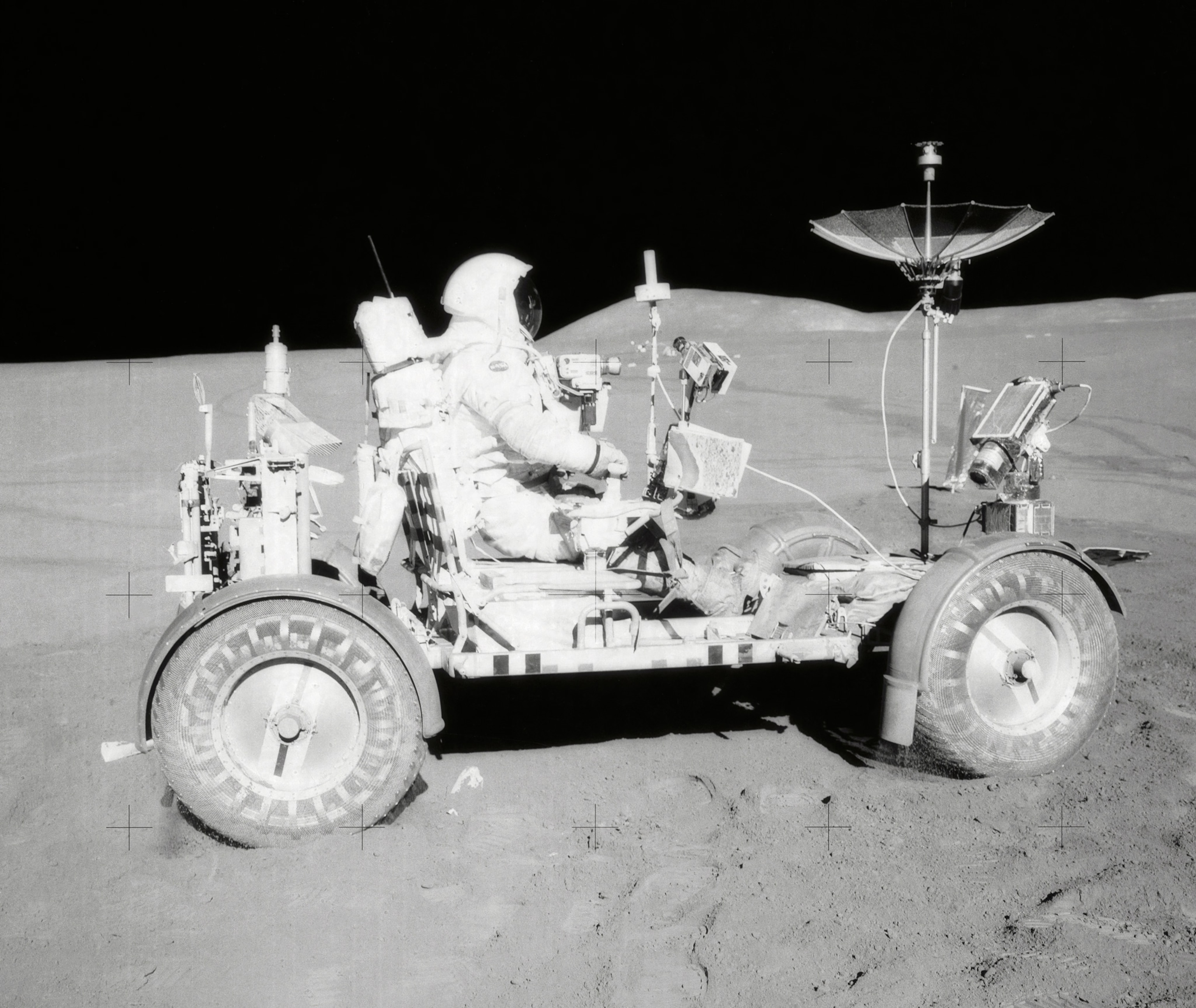

To survive all that, the Artemis astronauts will need more than the Apollo-era lunar roving vehicles. Those were single-use, skeletal-looking vehicles, front-loaded with a television camera and a communications antenna and fitted with two rudimentary metallic seats. Their design worked well for the 1970s; they shepherded astronauts of Apollos 15, 16, and 17 around the lunar surface for roughly 20 miles apiece.

The new LTVs are less of a sequel to the Apollo rovers and more of a full reboot. Instead of short-term scouts, Artemis requires long-term pathfinders. Each LTV is required to be capable of driving for 800 miles each year, and 12 miles each day, on a single battery charge, all while carrying a total payload mass—from deployable solar panels to sections of a lunar base—of at least 1,765 pounds.

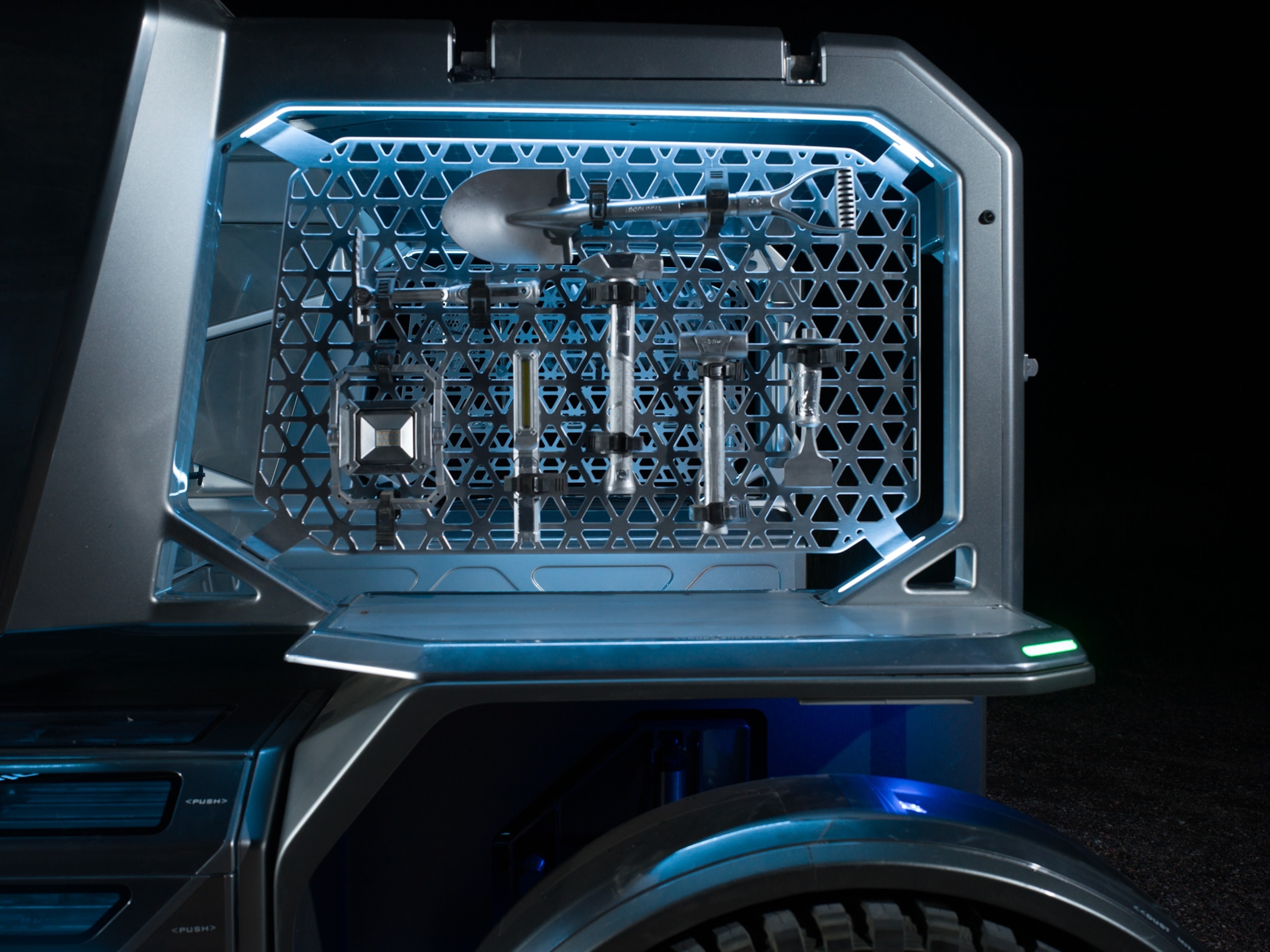

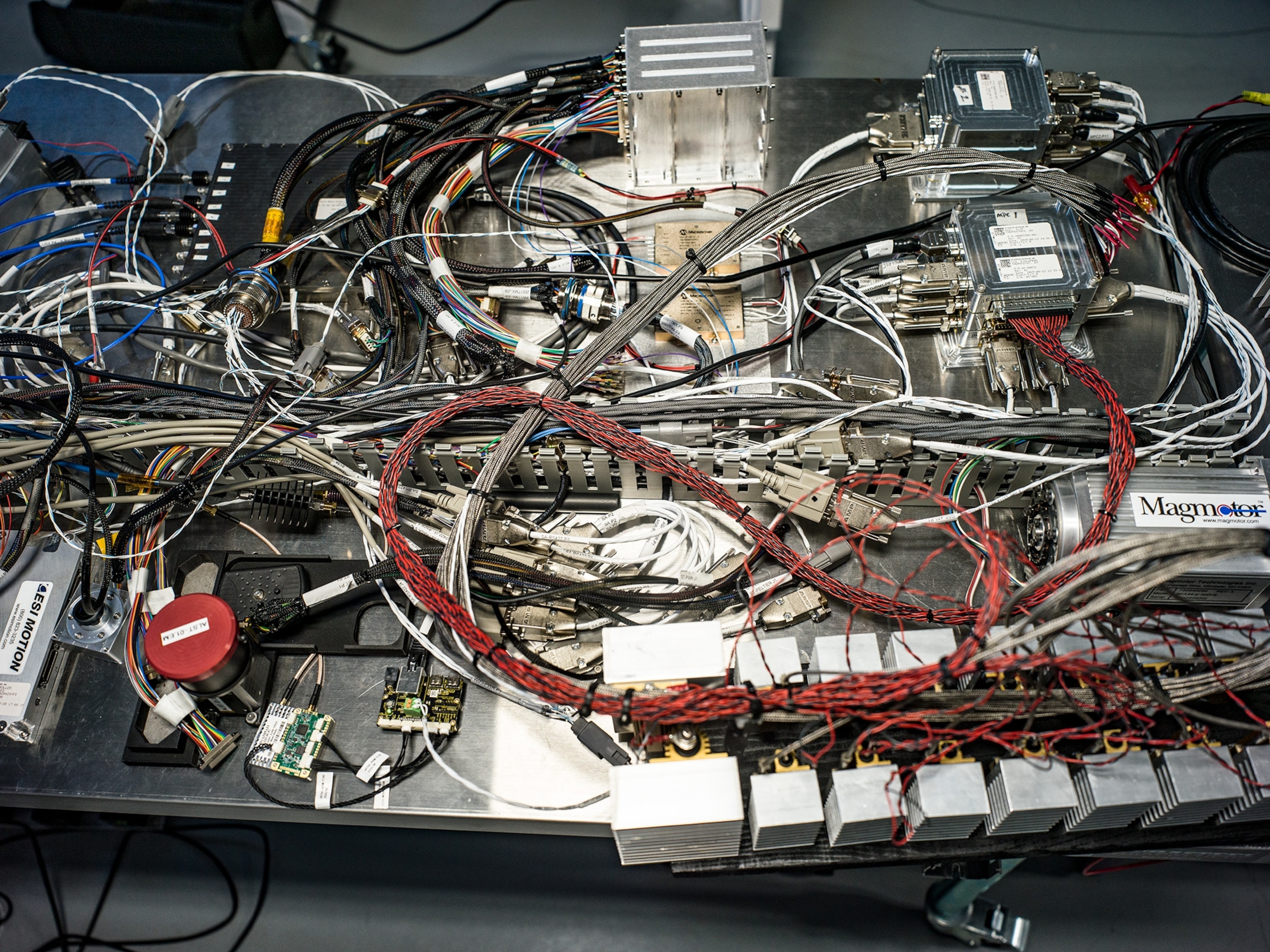

All three rovers are designed to use a robotic arm to assist with construction. This appendage can change its tool end whenever it wants by plugging itself into a series of enclosed drawers and switching out, say, a gripping claw for a drill, all by itself, with no human input. And each vehicle can be operated remotely, via pilots in control rooms back on Earth, and autonomously, where the vehicle’s own digital brain can safely steer it across the perilous lunar wilderness. No matter how it’s voyaging across the moon, each LTV has similar methods of perception: lidar, which uses hyper-frequent pulses of lasers to map out surroundings, and stereo cameras, which offer eyelike vision.

Each transport must persist for several years, requiring essentially no maintenance. Its electronics systems must be able to stay warm enough in shaded craters. It has to be shielded from corrosive dust. And it will be laden with armor—specifically, multilayered shielding (think of lasagna but replace the sheets of pasta with metallic alloys). This means that any errant speedy rocks will see their impact energy spread out rather than focused on one part, lowering the chances that any single micrometeorite can wreck the astronauts’ ride. Each rover will also use NASA’s newly invented electrodynamic dust shield to protect against the corrosive lunar dirt. This device is a series of ultrathin and transparent electrodes that can be overlain onto any surface of the LTV, from solar panels and cameras to navigation screens and radiators. It removes electrically charged particles by deploying an opposing electric current, and it can be left running or activated in bursts at the flick of a switch.

All three LTVs share similar design choices, in part because they were given the same set of base requirements by NASA. And yet, because each company has a novel vision for how astronauts will venture across the lunar south pole, all three designs are materially distinct. Becoming an instrumental part of the Artemis campaign, then, depends entirely on which vision inspires the space agency the most.

LUNAR OUTPOST

- Location: Southern Colorado Desert

- Name: Eagle

- LTV Type: Space Truck

NASA’s contest is a tall order. But Cyrus is up to the challenge. “It started when I was a kid,” he tells me, sitting at a small table in the middle of the desert. He was taken to NASA’s Johnson Space Center in Houston for its annual community chili cook-off. One year, there was an additional competition to build a space station with Lego blocks. “I love Lego. It’s the coolest toy,” he says. He came third in that competition. “I’m still a little salty about that. I’ve very competitive.” That drive convinced him to become a roboticist, and he eventually co-founded Lunar Outpost in 2017.

Although the company has ambitions for an array of space robotics and resources missions, for now its focus is designing an LTV for the moon—perhaps the ultimate Lego-building contest. Maybe this time Cyrus will win, with Lunar Outpost’s Eagle.

“It’s a space truck,” he says. “This is an easy way for people to latch on to it. Trucks are useful.” Although functionally a truck, this description may do Eagle a disservice. AJ Gemer, co-founder and CTO of Lunar Outpost, tells me that Apollo-era spacecraft prioritized function over form. Eagle’s retro-futuristic design is inspired by pre-Apollo-era sci-fi, “a time where people’s imagination wasn’t encumbered by the realities of spaceflight.” He wants anyone to take one look at Eagle and say, “Woah, that’s cool, I want to be a part of that.” (It’s unclear to what degree NASA will be swayed by aesthetics, but the world-famous space agency is certainly aware of the benefits of brand appeal.)

I am permitted to take a test-drive on one of the company’s various Eagle prototypes across the Colorado desert. The first thing I notice: The cockpit almost looks a bit too spacious—empty, even. But that’s by choice. Astronauts don’t have much mobility in their space suits. All three LTVs have been tested out by astronauts, including at Johnson Space Center’s Active Response Gravity Offload System (ARGOS) facility, where tethers attached to space suits simulate the one-sixth lunar gravity. “That test was critical to evolving our design,” says Gemer. They made sure that nothing about the LTV would obstruct the vision of the astronauts or provide an accidental tripping or head-banging hazard.

And instead of a wheel, there is a joystick—one not too dissimilar from the handle-like controls of the Apollo-era roving vehicles—which is far easier to use for thick-gloved astronauts.

Once we start it up, the Eagle prototype glides across bumpy, rock-filled desert. Despite its heft, the drive feels lightweight. And its suspension feels miraculous: While scooting over slopes and into craters, the change in elevation feels almost disconcertingly slight. It may be described as a truck, but being closer to the ground, I feel more like I am in the world’s most rugged, stable quad bike.

Future Artemis astronauts will be able to drive Eagle at a top speed of 16 miles an hour. This is as fast as you’d ever need to drive on the moon, whose lack of atmosphere and weaker gravity make braking take far longer than on Earth. Those astronauts will be pleased to know that the LTV also feels nearly impossible to tip over as I meander through the scrub.

Cyrus and his team hope their experience driving their rig on terra firma will give them an edge in NASA’s contest. “A lot of us do off-roading in Colorado,” he says. And that has inspired several design choices for their LTV. Geologic tools don’t have to be concealed within the vehicle; on the LTV I am shown, they are stuck to a variation of MOLLE panels: grids that allow drivers (be they Earthlings or astronauts) to attach and detach tools to them with ease. “Why reinvent the wheel?” says Cyrus.

Speaking of which, the makeup of Eagle’s tires, courtesy of Goodyear, is still proprietary, but Cyrus notes they’ve “done an insane amount of testing” on them, including on 30-degree lunar-like slopes, in thermal vacuums, and in torturous machines designed to spin them until they disintegrate. (In space, if an LTV tire ruptures, it could be an unfixable problem because—at least for now—there aren’t garages on the moon.)

And although a towable trailer can be attached to Eagle, there’s an expansive storage space behind its cockpit, which allows the vehicle to carry 2.4 tons of equipment (including two astronauts). Like the Colorado desert around us, the moon has plenty of jagged and precariously uneven patches. “You don’t want to have to tow a trailer to be able to accomplish your mission,” says Cyrus.

Colorado’s dust is nowhere near as corrosive as the moon’s, so regular off-roading protections won’t work for Eagle. That’s why, as well as sealing off all gears and sockets from the exterior environment, the company’s engineers designed the underside of the chassis with a series of grooves and pathways allowing the incisive dust to flow right through.

Colorado’s southern desert has been a huge help for the team. But “nothing beats operating the rover in space,” says Cyrus. Although he’s excited to see it used commercially, the thought that Eagle “could be the backbone of the Artemis mobility program” is what really animates him. “We just had a Lego set released,” he says—a minute version of Eagle. Seeing that in the store “was one of my favorite moments of my life so far.” I imagine it’ll be a close second to seeing Eagle on the moon itself.

ASTROLAB

- Location: Hawthorne, California

- Name: Flex

- LTV Type: Nimble Crustacean

It’s difficult to describe what I’m looking at. It’s a boxy, silver, metallic oddity –on wheels. It wouldn’t look out of place in The Expanse. This is the Flexible Logistics and Exploration, or FLEX, rover. It is the singular developmental focus of Astrolab. And they’re confident it’s the avant-garde ride NASA’s looking for.

Astrolab founder and CEO Matthews started his career at NASA’s Jet Propulsion Laboratory, where he worked on the Spirit, Opportunity, and Curiosity Mars rovers. He then worked for SpaceX for a while—including on Starship, the colossal, reusable launch vehicle that will ship pretty much anything to the moon, from crew to cargo.

That experience with SpaceX got Matthews looking at our lunar companion differently. It shouldn’t just be a brief holiday destination for astronauts. It should be an inhabited place, a working environment. How could he help realize that vision? In January 2020, he founded Astrolab—and FLEX would become his solution. His team has zeroed in on a design that leans heavily on the robotics side of the equation.

“Our rover looks the least like a car,” says Matthews. Its elegant yet angular, horseshoe-like chassis is its most idiosyncratic feature. The open undercarriage can clamp onto any cargo below it, then drive it around—not dissimilar to how a female giant land crab carries eggs on its underside.

Astrolab’s compact headquarters are just down the road from SpaceX’s California campus. A vertiginous Falcon 9 rocket stage stands in front of the space technology company’s giant complex as a monument to its remarkable success. Astrolab has yet to feature anything similar. But not long after I arrive, their FLEX rover—the vessel for their aspirations—rolls onto the crowded parking lot out front, looming over nearby earthbound cars. The working prototype I am shown has a series of cubic compartments on the front, one that can house tools or robotic arm components. The two astronauts, instead of sitting, hop up to the cockpit and stand or lean back as they drive.

It has already been extensively tested in a range of extreme environments, including California’s Death Valley. It is now my turn. As a lifelong video game player, I feel oddly prepared to drive FLEX around the parking lot; the sizable but compact vehicle is once again commanded by a joystick.

Indeed, piloting it invokes the same sort of glee I experienced when playing with a new toy as a kid. There are constant smile-induing discoveries. While making sure not to crash FLEX into any of the passing cars (and baffled drivers), I amble back and forth, spin around on the spot, change the suspension so the vehicle’s sides can be angled closer to the ground, and strafe from side to side. Turning a full 180, I see a separate joystick (a unique feature of this rover) and use it to drive the LTV as if the back is now the front.

FLEX is a remarkably maneuverable rover. “It’s all in the name,” Matthews says. “The whole idea is that it’s flexible and versatile.” This is, in part, thanks to its wheels—which aren’t just very dexterous but also made of some seriously clever stuff. You can’t use rubber on the moon because it becomes extremely fragile at lunar temperature extremes. So Venturi, a Monaco-based automotive maker, has crafted bespoke tires made of a type of novel silicone, a glass composite, and some stainless steel in a strange sandwich configuration.

That material alchemy alone can take the tires to temperatures of minus 240°F. “Which is still not cold enough, so we have embedded heaters in the tires to bring it up to that operational temperature,” says Matthews, noting that designing a rotating heater was far from easy.

And although FLEX doesn’t automatically come loaded with spare wheels, its key internal systems are duplicated within the rover. “There’s two sets of computers, there’s two batteries, there’s two power distribution units,” says Matthews. That way, a single micrometeorite strike or electronics malfunction in one component won’t incapacitate the rover. “It’s really two rovers in one.”

FLEX really feels like a mash-up of a Mars rover and a space-age cargo hauler. It’s designed to work in a pinch on any part of the lunar landscape, to carry any cargo, to be easily modifiable; even the standing crew section can be removed to make room for larger payloads.

With its cuboid shape and Mars rover-like appearance, FLEX is less stylized than Eagle. As intended, it’s explicitly functional. Matthews hopes NASA buys into that ethos. “To be providing mobility to humans for the first time in more than 50 years on the moon? That’s incredible to think about.” But ultimately, he says, he wants FLEX to be “the picks and shovels of the new moon rush. We want to be the thing that’s enabling anyone else who’s got interesting ideas to make money on the moon.”

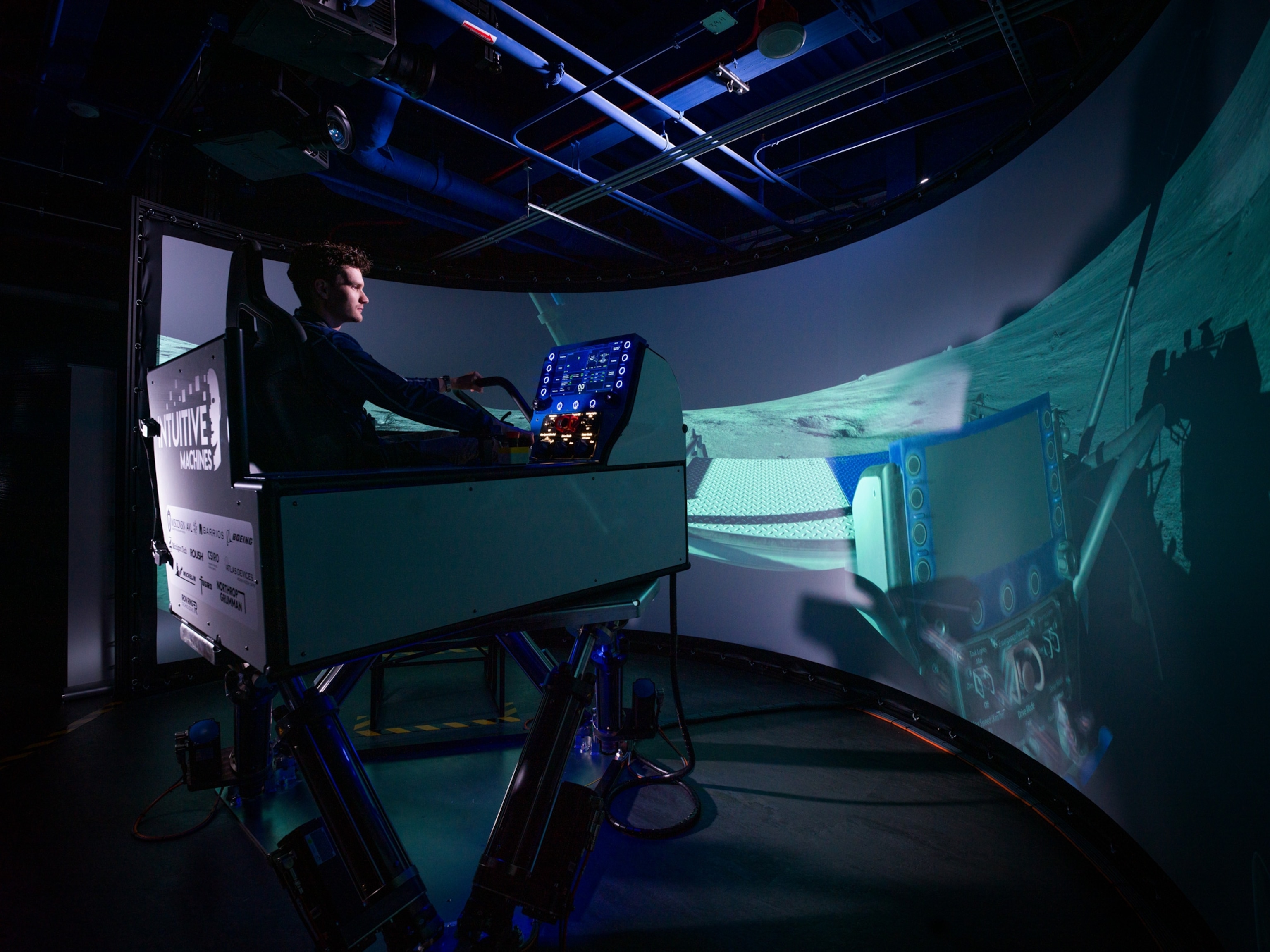

INTUITIVE MACHINES

- Location: Houston, Texas

- Name: Moon Racer

- LTV Type: Space-Age Dune Buggy

The employees of all three companies take inspiration from science fiction, but Intuitive Machines wears those influences most proudly.

I’m standing in front of a model of the company’s Reusable Autonomous Crewed Exploration Rover—also known as the Moon RACER. A pair of lucky dice like those decorating the Millennium Falcon’s cockpit dangle from the wire frame of the drivable RACER prototype—a vehicle resembling a cross between a dune buggy and the Warthog vehicle from the Halo video game series. Intuitive Machines is hoping that the familiar silhouette of RACER—the least alien design of the three rovers—will find favor with NASA. As engineer Reed Mulloy puts it: “Let’s be hyper-capable … but let’s look supercool doing it.”

Sitting in the driving seat, which hangs the closest to the ground, I take the joystick-controlled RACER for a spin around the facility, onto the roads, and (with encouragement from Mulloy) mount the curb at full speed. RACER bounces up onto the grassy knoll and darts about with ease. Even though its top speed is around 10 miles an hour, it feels speedy and spry. Things feel bumpy but fun; something about it reminds me of a thrilling fairground ride.

The name RACER is designed to evoke a sense of flair. And it works: While all three LTVs are very entertaining to drive, RACER is the most enjoyable one to control. As I quickly twist and turn my way about under the roasting summer sun, I can easily imagine astronauts grinning and doing much the same under an ink black lunar sky.

As ever, each major system is hardened against errant micrometeorites and solar outbursts. “We meet that requirement that no single impact can take out the vehicle,” says Gary Spexarth, their LTV program manager. And they have as much confidence in their Michelin-developed tires as the competition. “Michelin’s tested them in liquid nitrogen, submerged them,” he says, explaining the tires are cold-tolerant down to temperatures of around minus 320°F.

Their rover isn’t as modular as FLEX or as heavy-duty as Eagle. But because it looks and drives like a dune buggy (aside from its joystick), it’s the zippiest LTV of the three. “Art is an expression of the artist,” says co-founder Crain. “The design of the other two vehicles … reflects their robotics emphasis and background. We’re a little bit different.”

Of the three companies, Intuitive Machines, which was founded in 2013, is the most accomplished—and the most flamboyant. Markers of their past triumphs can be seen everywhere. A plaque near the entrance to their complex says: DEFYING IMPOSSIBLE SINCE 2023. That year, the company went public. The very next year, they became the first private company to land a spacecraft on the lunar surface. They repeated this feat in 2025—although both of their two landers tipped over upon arrival. Their goal, says Spexarth, is “expanding the lunar economy.” As well as landers, they are working on building lunar communications networks and Earth reentry vehicles.

Although both FLEX and Eagle can tow trailers if they need to, RACER’s design makes the towing capability more explicit—a key element rather than a bonus feature. “I could put a science lab, with its own power generation and its own comms unit,” says Crain. “You could have an oxygen extraction unit on board. You could have a small nuclear power plant.” RACER may look a bit like a souped-up go-kart on its own. But, particularly with the trailer attached, “the best analogy for people to think about is a tractor on a working farm.”

Like Lunar Outpost’s Eagle, testing RACER with astronauts—including Charlie Duke (of Apollo 16 fame) and Harrison Schmitt (Apollo 17)—encouraged the team to simplify the design of their LTV, by advising they forgo steps to enter the vehicle. Schmitt told them: “You don’t need steps. You just need a handrail to pull yourself up, because it’s one-sixth [gravity],” says Spexarth.

They have also enlisted the services of Atlas Devices, a company that works with the military and special forces to build powered winches that can launch soldiers onto waiting helicopters. “If an astronaut is incapacitated, how do you get them into the vehicle?” asks Spexarth. Atlas has crafted a winch specifically for RACER, one that’s resistant to lunar levels of abrasive dust and radiation to ensure one astronaut can quickly load their KO’d partner into the LTV.

From the breadth of industry partners that have joined their endeavor to the gung ho vibe of their engineers, the company behind RACER comes across as the most openly assured of the three. “There is no substitute for experience,” Crain says. He was referencing his anticipation about testing RACER on the moon itself—but he could have easily been referring to the company’s own spaceflight legacy. As die-hard fans of the Star Wars universe, they were all probably thinking the same thing about their LTV: The Force is strong with this one.

Who will win?

When contacted about the competition—the winner of which is expected to be announced by the end of the year—NASA declined to comment. But the space agency’s judges have their work cut out for them. All three companies have far exceeded NASA’s minimal requirements for the LTVs.

That’s in part because all three are seeking to go to the moon no matter what happens. “All three of the competitors will have solutions that will work,” says Crain. They have as much of an eye on the interests of their commercial partners as they do on the space agency itself.

Lunar Outpost, Astrolab, and Intuitive Machines may have conjured up very different moon rover designs. But each company’s team members have the same intense, almost childlike verve for space exploration.

For the public, the LTVs make the new lunar space race “a lot more tangible,” says David Paige, a planetary scientist at the University of California, Los Angeles, who’s helping design a scientific instrument for NASA’s chosen LTV. While the upcoming Artemis II mission next year will return humans to lunar orbit for the first time in a half century, the rovers help us imagine what future explorers will do when they set foot on the moon’s unfamiliar south pole. Envisioning them building a base is exciting. But picturing a moon racer doing donuts on the lunar surface is electrifying. “This is by far the coolest lunar mission ever, even eclipsing Apollo—finally,” Paige says.